Smarter NC Starts with Smarter Structure

To lead a high-performing NC team today, structure matters just as much as skill. From tool libraries to simulations, the right processes give programmers the confidence and consistency they need to deliver faster, better results.

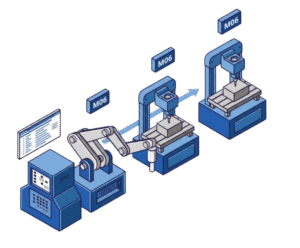

01 Standardized Posts Prevent Costly Mistakes

Consistent M-codes and unified post logic across machines reduce confusion, simplify onboarding, and ensure smoother handoffs from programming to the shop floor.

02 Templates Save Time and Improve Results

Reusable CAM templates for recurring operations eliminate manual setup work, expedite delivery, and ensure that your best practices are consistently followed.

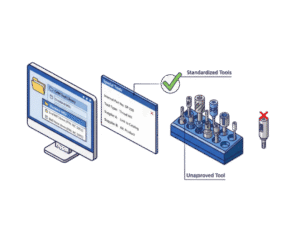

03 Shared Tool Libraries Keep Everyone Aligned

When all programmers use the same tool lists and definitions, collaboration is easier, tool sourcing is clearer, and the chances of a mismatch drop to zero.

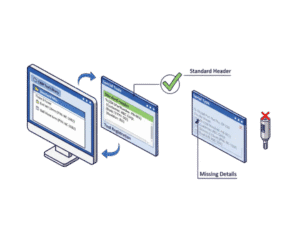

04 Consistent Headers Improve Traceability

Every NC file should begin with a clean, structured header that includes the part number, version, date, and customer. It’s a small habit that creates big clarity downstream.

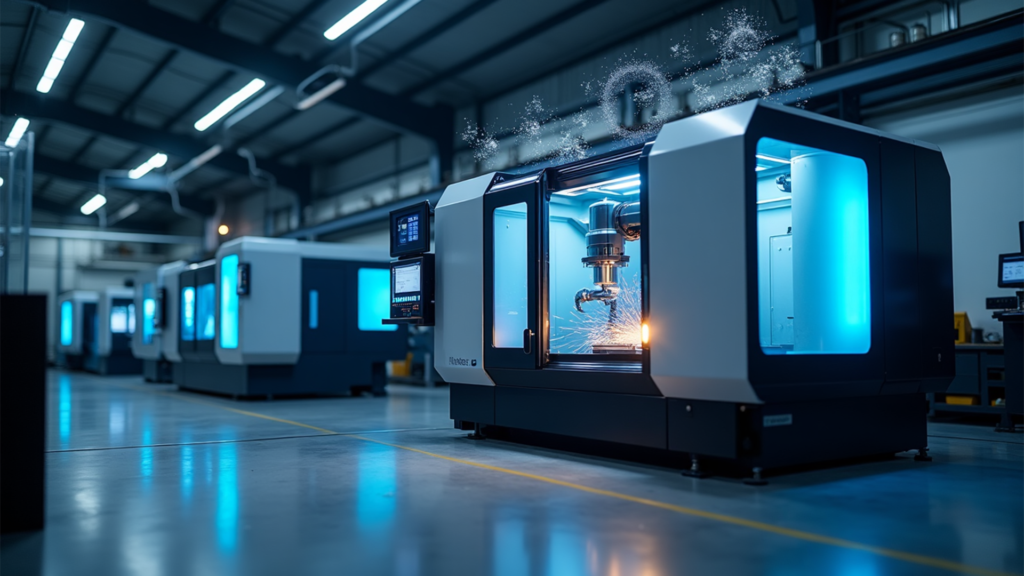

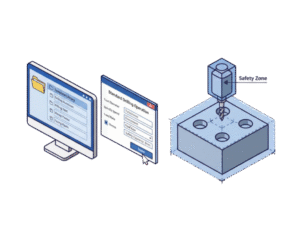

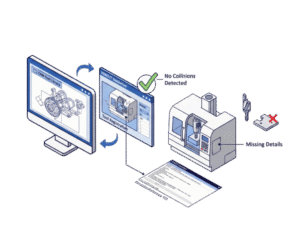

05 Running Simulations Prevents Crashes

Running simulations before sending code to the floor protects machines, tools, and schedules. It’s a small investment that prevents big problems.

06 Internal Guides Strengthen the Team

Create a programmer’s playbook with best practices, cutting speeds, and machine-specific notes. It helps new hires ramp up and maintains high quality.

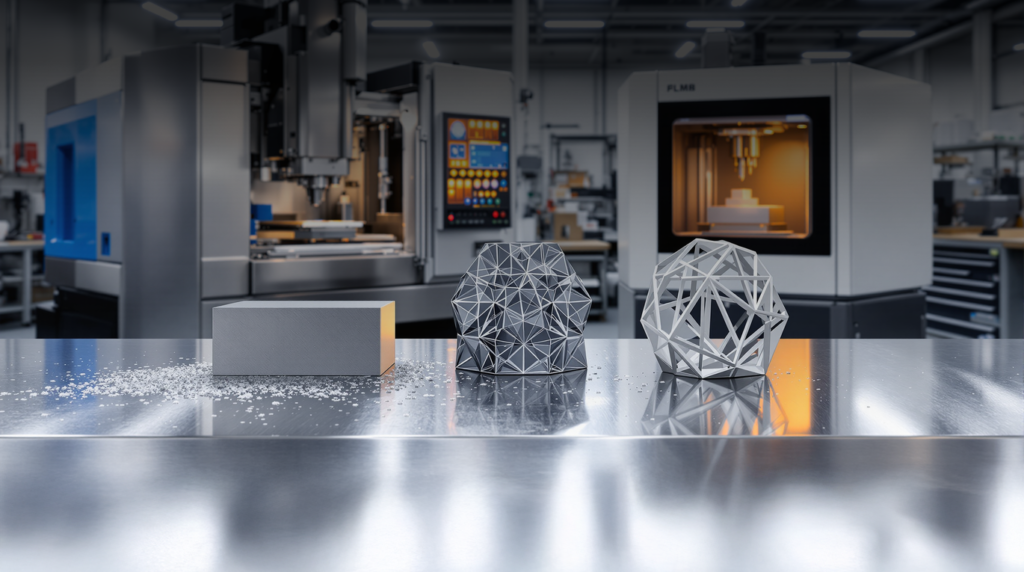

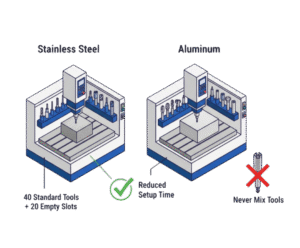

07 Material Allocation Reduces Setup Time

By dedicating machines to specific material types, tool changes are minimized and setup time is reduced, making the entire floor more agile.

08 Tracking Mistakes Leads to Real Improvement

Reviewing common programming errors and revising your workflows accordingly turns issues into insight and drives measurable progress.

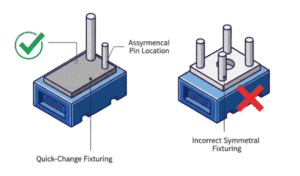

09 Smarter Fixtures Speed Everything Up

Quick-change and asymmetric fixture designs eliminate rework and reduce uncertainty, allowing operators to work faster and with greater confidence.

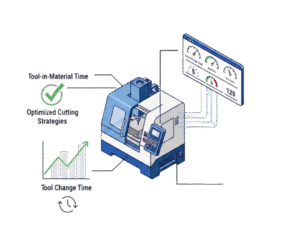

10 Real Data Drives Better Programming

Monitoring runtime, tool usage, and idle time enables you to tune strategies based on reality, rather than assumptions. Every second saved counts.

How LimitlessCNC Supercharges These Best Practices

LimitlessCNC helps NC teams turn these principles into practice. Our AI CAM Agent learns from your data and workflow, providing real-time programming suggestions that reduce time and minimize errors, without requiring changes to your entire system. It’s not about replacing people. It’s about helping them do their best work, faster.