Our AI agent enhances CNC programming with intelligent recommendations, automated optimizations, and real-time adjustments.

Use the AI to analyze the design geometry and create machining operations based on all relevant properties for your team’s use.

Identify the part geometry to match it with the ideal operation type by assessing the shape, features, and required machining processes.

Optimize cutting tool selection by assessing the material, geometry, and operation type, recommending the most efficient tool for precision, speed, and tool lifespan.

Calculate optimal feed rates and spindle speeds based on material properties, tool selection, and machining conditions to maximize efficiency and minimize wear.

Assess historical data, tool wear, and material properties to forecast cutting forces, surface quality, and overall process efficiency and performance.

The AI agent is connected to your NX session. User actions are then used as input while generating corresponding operations as output.

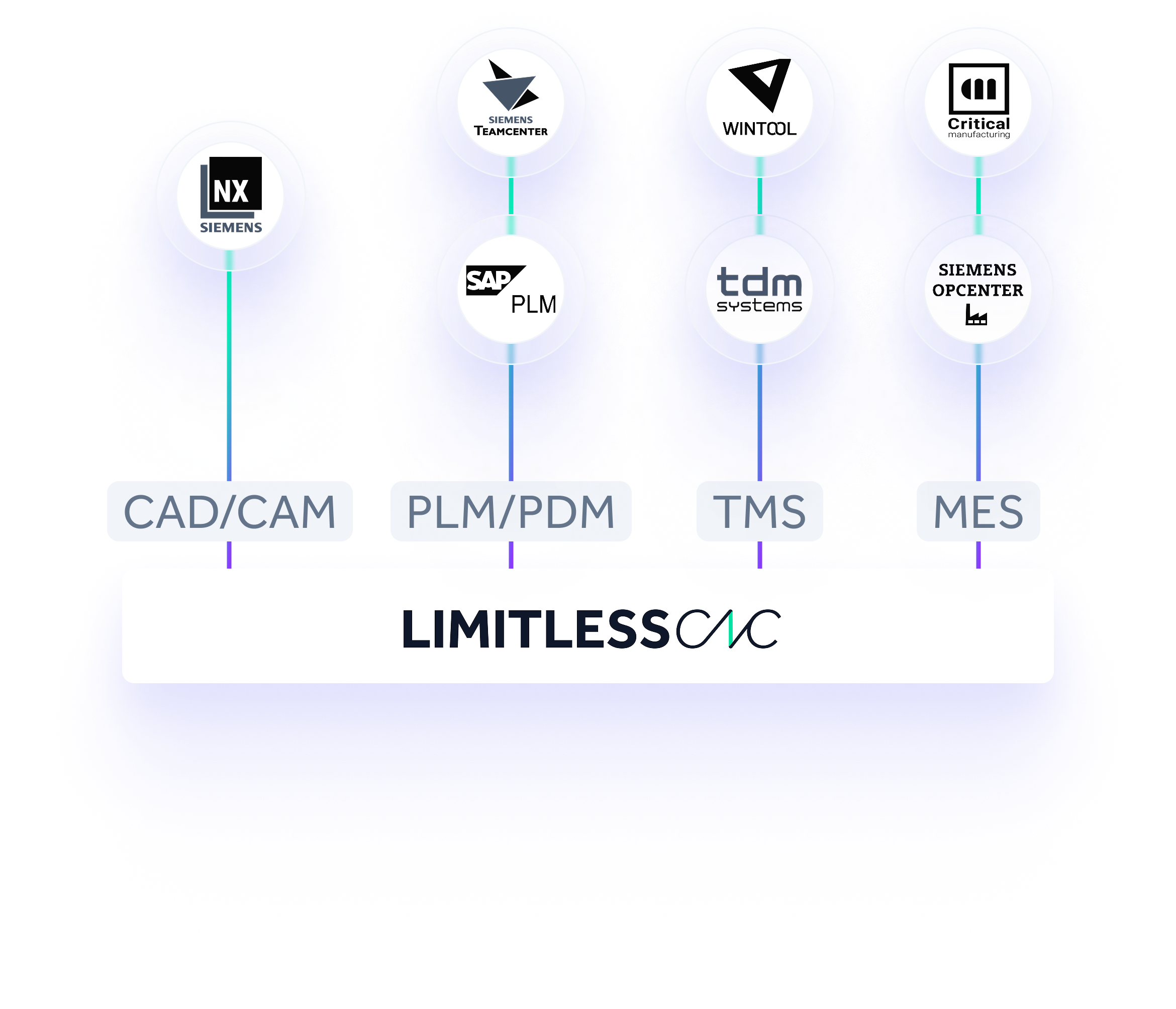

API integration syncs with new CAD/CAM data, eliminating the need for manual copy-pasting.

Read-only syncing to capture machining and setup time and more, which then improves your AI agent’s performance.

Full read-only syncing with your tool types and availability, so there's no need to manually connect tool libraries.

Easily installed right into the environment programmers are already used to.

Gets context about family parts, tool libraries and other team best practices form historical process data.

As the team uses the agent, the AI training and recommendations improve based on user feedback.

Our team of (human) experts is dedicated to making your onboarding smooth and clean and to assist with any issue in minutes.

Backed by advanced cloud security that meets SOC2 and ISO 27001 standards, our custom AI model is built exclusively for your organization.

We make sure your know-how is preserved, using the AI agent to reduce time spent training new team members to meet your machining needs.

Supercharge NX-CAM with LIMITLESS AI

The AI agent will use details from your custom templates and macros, allowing it improve on your existing automations.

Recommendations are checked and validated while considering machine limitations, fixtures, position, and tool assembly geometry.

Optimal machining strategy for your GD&T requirements for specific surfaces, even when requirements are tight.

LIMITLESSCNC delivers faster programming, optimized machining, and streamlined operations, helping you boost efficiency, accuracy, and production capacity.

Experienced CNC machinists take more strategic tasks instead of repetitive jobs and supervising juniors.

Production and output speeds up by reducing your programming time by up to 50% compared to previously.

Production-stopping mistakes decrease with unprecedented accuracy and precision optimizations.

Training between employees empowers professional growth and better outcomes.

Maximize production with smarter, more efficient manufacturing

See the measurable impact, higher output, lower costs, and smarter machining with AI.

50

%

Increase in programming productivity

Less reprogramming time, reduced ramp-up for employees, plus fewer trial and error iterations means more output and less machine wear.

15

%

Reduced lead time

With ready-for-production programs prepared in advance, machines never need to wait empty. With our AI Agent, setup time is cut in half.

90

%

Fewer human errors

Using incorrect feeds and speeds causes costly damage and down time to production. Avoid scraped parts, damaged spindles and QA delays with