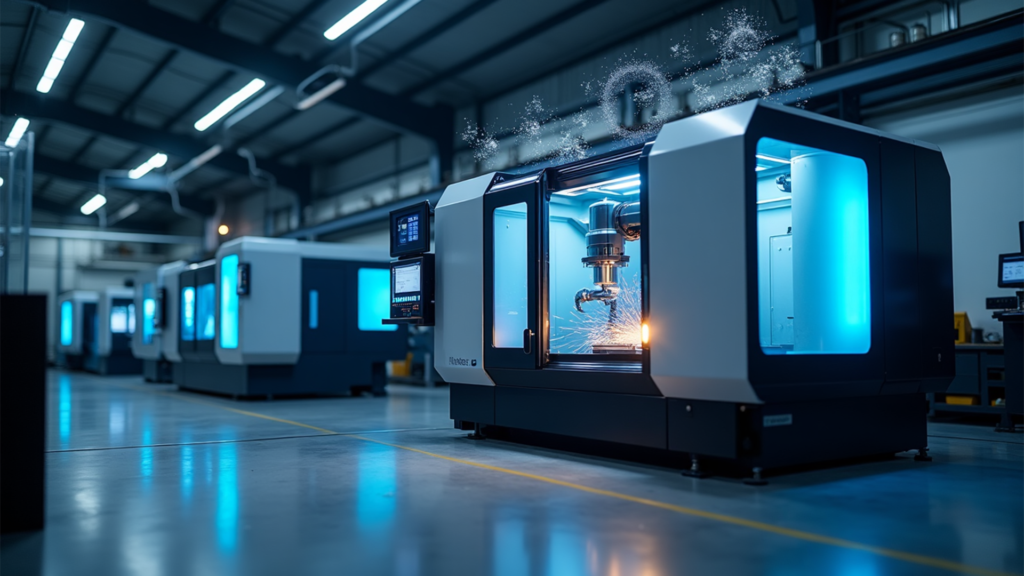

AI CNC programming reshapes the manufacturing scene today. Recent studies show 93% of companies consider it a vital technology to stimulate growth and create breakthroughs. Many machinists express concerns about job displacement, but data reveals a different reality. Business projections indicate 64% expect AI to boost efficiency, which makes skilled machine operators more significant than ever.

The combination of CNC technology and AI empowers human expertise rather than replacing it. AI-driven systems make uninterrupted production cycles easier and minimize human error. These systems still need skilled machinists who can program, oversee, and optimize them effectively. This piece explores AI’s role in making machinists more valuable and creating new opportunities in the field.

The Evolution of CNC Technology and Skills

CNC technology’s experience started in the late 1940s when John T. Parsons envisioned using numerical data to control machine movements. MIT developed the first experimental milling machine in 1952 that showed how punched tape could direct precise tool movements [1]. This groundbreaking approach started a fundamental transformation in manufacturing processes.

The 1960s and 1970s saw computers transform simple NC (numerical control) machines into more sophisticated CNC (computer numerical control) systems. Microprocessors arrived in the 1970s and dramatically reduced costs, which made CNC technology available to smaller manufacturing operations [2]. The 1980s brought significant advances with CAD/CAM software integration that connected design directly to production and streamlined manufacturing [3].

Machinist skills changed from manual dexterity to programming proficiency and problem-solving capabilities as CNC technology matured. A study of valve manufacturing plants showed that 85% of CNC-adopting companies reported problem-solving skills became more important, compared to 68% of non-adopters [4]. These plants were 75% more likely to organize workers into problem-solving teams [4].

Modern CNC machinists need a diverse skill set that covers technical knowledge, software proficiency, and critical thinking. Attention to detail is vital since minor errors can damage expensive equipment [5]. CNC programming has progressed to include AI and machine learning algorithms that enable adaptive machining strategies to boost efficiency and precision [6].

New Skills Machinists Need in the AI Era

AI technologies are altering the map of manufacturing workflows, and CNC machinists need to adapt faster. Recent studies show that while technical proficiency remains essential, AI integration requires skills beyond traditional expertise.

Technical skills are the foundations of machining excellence. Today’s operators must become skilled at G-code programming and understand how AI systems interpret and optimize toolpaths. Companies that adopt CNC report that problem-solving skills have become vital, as machinists tackle complex AI-human interactions on the factory floor.

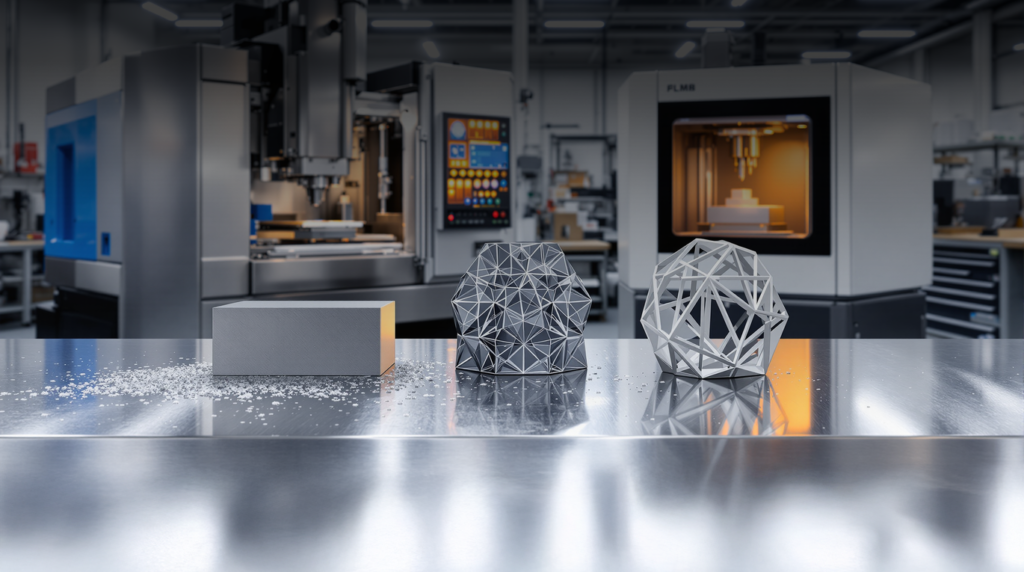

The AI era has made precision and attention to detail more crucial. AI machines can generate trillions of possible manufacturing approaches for a single component. This means machinists must develop good judgment to review AI-suggested strategies and pick the best approach for specific uses.

Data analysis has emerged as a major skill gap, with 52% of tech leaders seeing this deficiency in their organizations. Modern machinists must read data from CNC machine sensors to spot issues that humans might miss.

Machinists should accept new ideas and keep learning about emerging technologies to stay relevant. SC Training offers specialized courses in CNC machining basics, while TITAN’s online academy provides complete training in CAD/CAM and CNC operations. Certifications from organizations like NIMS are a great way to get better job prospects.

Adaptability is maybe even the most valuable skill, as 42% of companies will focus on AI and big data skills by 2027. People who keep improving their skills and see AI as a partner rather than competition will succeed. As one industry expert says, “AI won’t replace you, but someone who uses it better will.”

The machinist’s role isn’t shrinking—it’s becoming more strategic, evidence-based, and ended up more valuable.

How AI Elevates Machinist Expertise

AI has become a powerful ally in CNC machining, serving as both navigator and partner to experienced operators. Similar to a GPS for toolpaths, AI guides machinists by suggesting optimal strategies and offering multiple solutions to complex manufacturing challenges [7]. This shared approach strengthens the machinist’s role and enhances their expertise and decision-making capabilities.

AI makes CNC machining more precise through immediate data analytics. Studies show that AI-powered quality control systems can reduce defect rates by up to 50% [8]. AI detects tiny deviations that human operators might miss by analyzing inputs from sensors embedded in CNC machines. This ensures higher consistency in final products.

The nature of machinist work changes with AI rather than disappearing completely. AI takes care of repetitive tasks while machinists concentrate on more complex, higher-value activities. A digitized life underwriting team found that this transformation requires weekly virtual meetings between operators and AI developers to improve processes continuously [9].

AI-driven maintenance systems have proven to be groundbreaking. Research shows they can decrease costs by up to 25% and reduce unplanned downtime by 30-40% [8]. AI predicts potential machine failures before they occur by analyzing historical performance data and real-time sensor inputs. This allows teams to take proactive measures.

The human element remains crucial despite these advances. Even the most sophisticated AI needs skilled machinists to:

- Review AI-suggested strategies for specific applications

- Provide contextual understanding

- Oversee processes and fix errors

AI raises machinist expertise by managing data-driven aspects of production and enables humans to use their specialized knowledge more strategically. AI creates a new breed of technologically advanced manufacturing professionals instead of replacing machinists. Their value comes from knowing how to cooperate effectively with intelligent systems [10].

Conclusion

AI-powered CNC programming represents a major milestone in manufacturing development. This advancement mirrors the fundamental change from manual to computer-controlled machines that happened decades ago. The technology creates new opportunities for growth and specialization instead of replacing skilled machinists. Companies that use AI show higher productivity and still need expert machine operators to guide these advanced systems.

Adaptable machinists have a promising future ahead. They become great assets to their organizations by mastering both traditional expertise and new AI capabilities. The numbers tell a compelling story. AI-boosted operations cut defect rates in half and reduce maintenance costs by 25% when skilled operators work with these systems.

The path forward is clear. Smart machinists will see AI as a valuable partner that handles routine tasks. This allows them to tackle complex problem-solving and make strategic decisions. The combination of human expertise and artificial intelligence doesn’t just keep machinists relevant – it makes their specialized knowledge more vital than ever.

References

[2] – https://www.americanmicroinc.com/resources/evolution-cnc-machines/

[3] – https://resources.hartfordtechnologies.com/blog/the-evolution-of-cnc-swiss-machining-technology

[5] – https://www.xometry.com/resources/machining/cnc-machinist-skills/

[6] – https://etherealmachines.com/blog/advancing-cnc-efficiency-innovative-toolpath-optimization-techniques/

[7] – https://www.autodesk.com/products/fusion-360/blog/cnc-machining-is-artificial-intelligence-taking-over/

[8] – https://blog.3ds.com/brands/delmia/revolutionizing-machining-operations-with-artificial-intelligence/